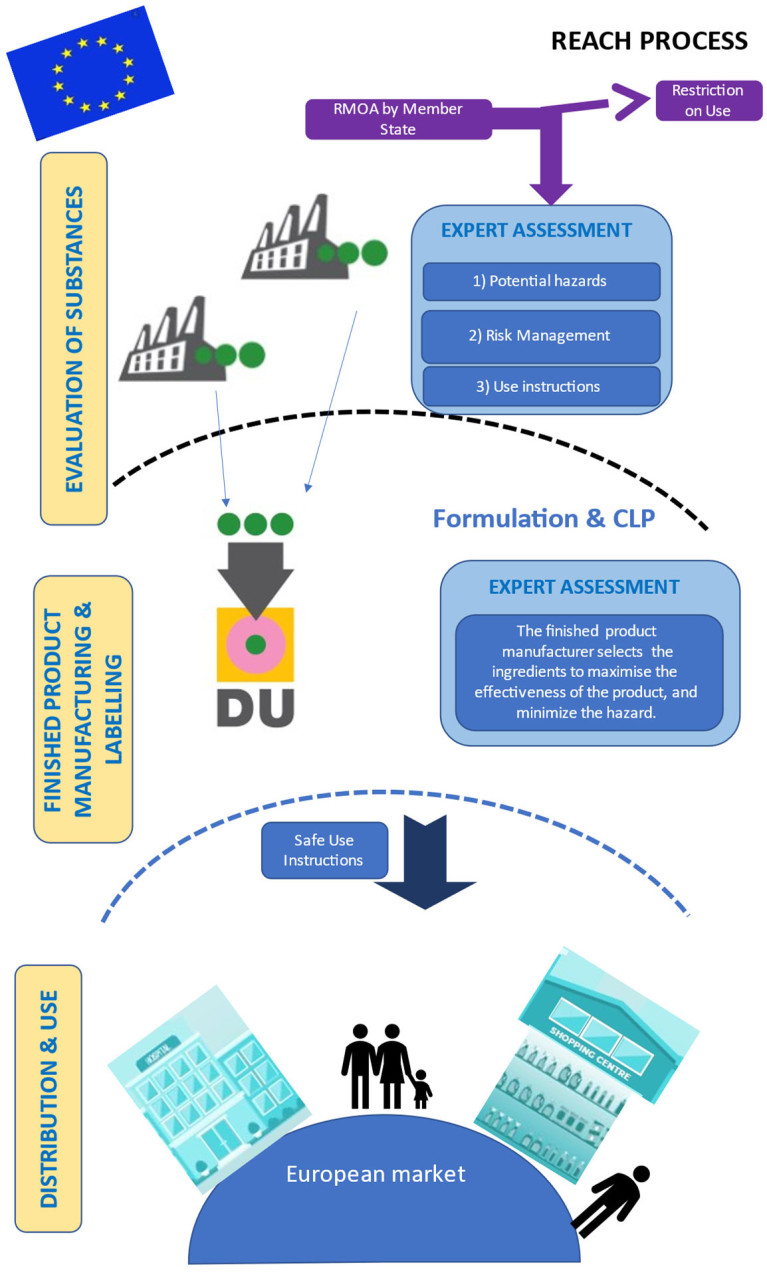

REACH is a European Union Regulation that aims to improve the protection of human health and the environment by identifying the risks that can be posed by chemical substances. REACH applies to all chemical substances in our day-to-day lives, for example in cleaning products, paints as well as in articles such as clothes, furniture and electrical appliances.

- As a first step chemical ingredient suppliers have to submit all information on the substances demonstrating that the risk of a substance is properly managed and that it can be used safely.

- The second step involves an analysis by a product manufacturer as to how the risks can be managed if that substance is used on the market e.g. in a cleaning product. Taking skin corrosion as an example, a way the risk can be managed is by wearing gloves during use of a product. A registration dossier with all this information must be submitted to the European Chemicals Agency (ECHA).

- Information on how to use an ingredient safely must then be passed down the supply chain from the ingredient manufacturer to the formulator.

- A final product manufacturer will then use the information from ingredient suppliers to formulate the products and place them safely on the market. Ingredients selected for this product will have been selected to maximise the effectiveness of the product while minimizing the hazard.

When added below a certain quantity, the hazards of a substance will be minimised. One common example is Acetic Acid, this is a key ingredient in vinegar. In its pure form Acetic Acid is corrosive to skin, but when it’s diluted at 4% in water, it is very tasty on salads and chips!

Any remaining information related to the safe use of the product will then be conveyed on the label. For example, that gloves need to be worn when using a product. This is another way to reduce hazard.

Think about a rainy day. On such a day there is the hazard of getting wet. You can thus use an umbrella, or raincoat. This is an action you take to reduce your exposure to the hazard. When driving, you wear a seatbelt, or drive more slowly. For chemicals the actions you need to take are written on the label of the product. It is for this reason that reading the label of a product is extremely important.

These four steps allow for the safe use of chemicals on the market.

For a small subset of ingredients, a more thorough assessment needs to be carried out. In these instances, the REACH process foresees that legislators make a submission for a “Regulatory management option analysis”. This happens in cases where there are concerns about a substance. Authorities then have the option to check if there are any further steps to be taken to ensure EU consumers safety. This could be additional actions to reduce the risk of a substance. If we stick to the example of a rainy day, this could be the introduction of better umbrellas or collecting information for a weather forecast.

This is a simple explanation of the REACH regulation. It is the is the most advanced and complex legislation of this type in the world. People across Europe work daily to provide expertise, both in companies and in authorities at national and European level, to apply and implement this process. Thanks to this thorough process, companies bring important products to the market to meet the daily needs of EU citizens, while following a system that aims to safeguard human safety and protect the environment.

What is the Regulatory Management Option Analysis? expand

- The EU authorities would: Ensure that the risks of that substance are well managed on the EU market.

- That there are some potential hazards of which the user should be aware of. In this case, the CLP regulation is there to ensure the user is warned of hazards through harmonized pictograms and phrases. The label should always be read carefully and followed so a product can be used safely.

- They could choose to grant an authorisation - the aim of the authorisation process is to ensure that substances of very high concern are progressively replaced by substances or technologies where technically and economically feasible alternatives are available.

- Or finally restrict the use of the substance, allowing for specified and limited use

Benefits by ingredient functions

| Function | Benefits |

|---|---|

| Flocculants | Treat unwanted contaminants in water, by forming clusters that can then be removed by filtration or settling |

| Opacifiers | Impart a milky, “lotion”-like appearance, to denote product characteristics such as mildness for sensitive skin |

| Encapsulated Fragrances | Capsules to enclose fragrances, to reduce the quantity of fragrance needed and to ensure it survives the washing, rinsing and drying proces. |

| Wax | Wax has a number of different beneficial functons. It can be used to add a protective coating to surfaces that can be polished to shine and improve appearance. It can also be used as a binder to ensure that ingredients hold together in the required shape. Wax is also used to provide a sustainable steady burning fuel for candles. |

| Viscosity Controlling Agents | Controls the thickness of the product. |

| Solvents | |

| Solubiliser | Improves the solubility of one or more product ingredients. |

| Soaps | These salts of fatty acids are more commonly known as "soaps". They may be added to the product in the form of the fatty acids; in the product matrix the salts will be formed. The soaps are commonly used surfactants in laundry and cleaning products. |

| Sequestrants | Prevents free metal ions from causing any adverse effects on product performance, appearance, or stability by reacting with them. |

| Preservatives | Protects products from microbial growth and spoilage. Preservatives are required to prevent product damage caused by micro-organisms and to protect the product from accidental contamination by the consumer during use. " |

| Preservatives (FA releasers) | Protects products from microbial growth and spoilage. Preservatives are required to prevent product damage caused by micro-organisms and to protect the product from accidental contamination by the consumer during use. " |

| Phosphonates | Used in products to remove soap scum and mineral deposits that are caused by hard water. By binding to the soap scum or deposit, it allows them to be rinsed away. (Phosphates and Phosphonates are no longer used in EU detergents and cleansers. Limitations were imposed by the Detergent Regulation for their use in consumer laundry detergents and consumer automatic dishwasher detergents due to environmental concerns) |

| Phosphates | Make the cleaner more effective by removing calcium and magnesium.* (Phosphates and Phosphonates are no longer used in EU detergents and cleansers. Limitations were imposed by the Detergent Regulation for their use in consumer laundry detergents and consumer automatic dishwasher detergents due to environmental concerns) |

| pH Adjusters | Added to control the acidity/alkalinity of products. Every formula has an optimum pH to make it work best. For example, a formula that’s more acidic works better for soap scum removal. Its opposite, a formula that’s more alkaline, might be more effective at removing grease or greasy soils. We use pH adjusters to make sure we achieve the best pH for a particular job. Also, the pH of a formula can affect how long it lasts within a container – for example limiting its tendency to corrode a can, container or dispenser. |

| Oxygen-based bleaching agents | In detergents stains are removed by oxidation (bleaching). Oxygen-based bleching agent such as Sodium carbonate peroxide are used in laundry and cleaning products. During the wash, the peroxide is consumed and the carbonate remains. |

| Oxidising Agents | In detergents stains are removed by oxidation (bleaching) |

| Optical Brighteners/ Whitening Agents | Makes products or washed fabrics look brighter and whiter |

| Nonionic Surfactants | These surfactants do not have an electrical charge, which makes them resistant to water hardness deactivation. They are excellent grease removers that are used in laundry products, household cleaners and hand dishwashing liquids |

| Hydrotropes | Increases the solubility of the detergent in the product |

| Fragrances | Fragrance provides part of the sensorial benefits of a clean home or laundry and is a major element of product performance for consumers. Its benefits are both emotional (such as by signifying cleanliness, freshness or comfort) and functional (masking malodour). Fragrance is a key differentiator between products. |

| Foam controlling Agents | Helps prevent and excessive build up of foam to enable quick and effective rinsing of the product at the end of the wash cycle. |

| Fabric Conditioner Agent | Softens/conditions the fabric. |

| Enzymes | Enzymes are catalysts that increase the rate of chemical reactions such as digestion and growth processes. In the detergent industry, commercial enzymes are used to ensure a higher degree of stain removal, whiteness, fabric and color care, and overall cleaning performance. |

| Enzyme Stabiliser | Prevents deactivation of enzymes in liquid detergents |

| Emulsifiers | Emulsifiers are surface-active agents (such as a soap) that are used to create and stabilise an emulsion. Without emulsifiers the ingredients in some products would not be be properly mixed or would 'split' |

| Cationic Surfactants | In fabric softeners and in detergents with built-in fabric softener, cationic surfactants provide softness. Their main use in laundry products is in rinse added fabric softeners, such as esterquats, one of the most widely used cationic surfactants in rinse added fabric softeners.In household and bathroom cleaners, cationic surfactants contribute to the disinfecting/sanitizing properties |

| Bulking Agents | Added to increase the volume of a product through dilution, so that it can be applied at the correct concentration. |

| Builders | Reduces the effect of water hardness by removing calcium and magnesium ions and increases the effectiveness of the detergent |

| Bleach Precursors | Reacts in the wash to form bleaching substance |

| Bleach Activators | Allows a bleaching effect at lower washing temperature and thus helps save energy |

| Binders | Substances that are added to provide adhesive properties so that the solids stick together e.g tablets. |

| Anti-redeposition Agent | Prevents dirt in the wash solution being re-deposited on the clothes. |

| Antioxidant | Antioxidants preserve materials by preventing oxidation (i.e. reaction of the product with oxygen). This ensures that products do not 'go bad' (e.g. by discolouring) during storage before use. |

| Antifoaming Agent | Suppresses the formation of excess foam during production and/or consumer use. |

| Anticaking Agent | Prevents the formation of lumps in the product. |

| Anionic Surfactants | These surfactants are particularly effective at oily soil cleaning and oil/clay soil suspension. They can react in the wash water with the positively charged water hardness ions (calcium and magnesium) , which can lead to partial deactivation. " |

| Amphoteric Surfactants | These surfactants are very mild, making them particularly suited for use in personal care and household cleaning products. They can be anionic (negatively charged), cationic (positively charged) or non-ionic (no charge) in solution, depending on the acidity or pH of the water. |

| Alkalinity sources | Increases the alkalinity of the product to aid dissolution of dirt. |

| Additives | Ensures desirable product properties |

| Abrasive | Aids the removal of a variety of soils from various surfaces through mechanical action e.g. grime from kitchen/bathroom tiles, baked on foodstuffs from cooker tops etc. |

Different hazard types and how they are managed

| Function | Benefits |

|---|---|

| Skin irritation | Depending on the concentration at which the ingredient is added to make the final product effective, the final product may have skin irritating properties. In Europe, the pictogram |

| Eye irritation | Depending on the concentration at which the ingredient is added to make the final product effective, the final product may have eye irritating properties. In Europe, the pictogram |

| Eye corrosion | Depending on the concentration at which the ingredient is added to make the final product effective, the final product may have eye corrosive properties. In Europe, the pictogram |

| Skin corrosion | Depending on the concentration at which the ingredient is added to make the final product effective, the final product may have skin corrosive properties. In Europe, the pictogram |

| Respiratory irritation | Based on the ingredients in the formulation, there may be respiratory irritating properties to the final product. Make sure to Ventilate the room after use. |

| Skin sensitization | When exposed, those with an existing allergy may be triggered and have an allergic (skin) reaction to this ingredient. Thus, companies add these ingredients in the smallest effective quantity to ensure the positive effect in the detergent and list the ingredient on the label and online. This is done so that those with allergies can make informed choices and avoid products with ingredients that they are allergic to. |

| Environmental concerns of surfactants | To be placed on the market in Europe detergents have to follow the European Detergent Regulation which requires all types of surfactants used in detergents and maintenance products to be readily and ultimately biodegradable. (Link to biodegradability chapter) |

| Acute aquatic hazard/ Environmental concerns | In Europe, based on the composition of product, the pictogram |

| Flammable/explosive | This is not relevant for detergents due to the way these products are formulated either in water or as large granules thus eliminating the risk of flammability. |

| Do not mix with bleach activators | Some formulations can result in harmful chemical reactions if mixed with other ingredients. It is very important not to mix products together. |

| Release toxic gas if mixed with acid | Some formulations, especially those containing bleach, can result in release of toxic gas if mixed with acid. It is very important not to mix products together. |

| CMR properties | Each ingredient has a safe level below which it is safe for use. This ingredient is used in very small, and safe amounts, below the limit at which it cause any CMR properties. The final product will be safe for use. |

| Respiratory sensitization for Enzymes | Enzymes have been incorporated in consumer laundry and maintenance products since the 1970s. In case a high volume of airborne enzyme particles are repeatedly inhaled this might potentially lead to respiratory allergy. However, in laundry and maintenance products the enzymes are formulated in liquids or embedded in coated granulates. Thereby airborne enzyme particles is below safety concern and the risk which could potentially lead to respiratory allergy is removed. There is a lot of compelling evidence through widespread consumer experience over several decades that enzymes can be used safely in consumer products. |

| Acute toxicity/ Harmful if swallowed | Detergent and maintenance products should not be ingested |

| Environmental concerns for phophates and phosphonates - Risk of eutrophication in surface water | Phosphates and Phosphonates are no longer used in EU detergents and cleansers. Limitations were imposed by the Detergent Regulation for their use in consumer laundry detergents and consumer automatic dishwasher detergents due to environmental concerns |

| Ingredient INCI NAME | Amylaseview more |

|---|---|

| Other Chemical Names | |

| EC number | 232-567-7 |

| CAS number | 9000-92-4 |

| Function | Amylase is used in Detergent and Maintenance Products as an Enzymes Amylase enzymes break down starches and sugars for easier stain removal, such as gravy, ice cream, and condiments. Enzymes are catalysts that increase the rate of chemical reactions such as digestion and growth processes. In the laundry and dishwash detergent industry, commercial enzymes are used to ensure a higher degree of stain removal, whiteness, fabric and color care, and overall cleaning performance. They can also be found in some drain cleaners and other enzymatic cleaners. |

| Regulatory actions to ensure safe use | REACH registered Safe use assessed by experts along the supply chain |

| Regulatory measure under consideration - Status | |

| Date of updated information | |

| Risks | The Risk of an ingredient is based on its’ Hazards related to the Exposure Enzymes have been incorporated in consumer laundry and maintenance products since the 1970s. In case a high volume of airborne enzyme particles are repeatedly inhaled this might potentially lead to respiratory allergy. However, in laundry and maintenance products the enzymes are formulated in liquids or embedded in coated granulates. Thereby airborne enzyme particles is below safety concern and the risk which could potentially lead to respiratory allergy is removed. There is a lot of compelling evidence through widespread consumer experience over several decades that enzymes can be used safely in consumer products. |

| Ingredient INCI NAME | Formic acidview more |

|---|---|

| Other Chemical Names | |

| EC number | 200-579-1 |

| CAS number | 64-18-6 |

| Function | Formic acid is used in Detergent and Maintenance Products as a Preservative Water-based liquid detergents need a method of preservation, without this they would be contaminated by micro-organisms and result in product going to waste. Preservatives thus play a fundamental role in preventing product damage. They ensure durable shelf and storage life, thereby reducing product losses, and support sustainability by optimising use of resources |

| Regulatory actions to ensure safe use | REACH registered Reviewed under the Biocidal Products Regulation (EC) 528/2012 as well as REACH |

| Regulatory measure under consideration - Status | Under assessment for potential Endocrine Disrupting properties - on ED list |

| Date of updated information | Sep-21 |

| Risks | The Risk of an ingredient is based on its’ Hazards related to the Exposure Eye corrosion : Depending on the concentration at which the ingredient is added to make the final product effective, the final product may have eye corrosive properties. In Europe, the pictogram appears on the label of household detergents and cleaning products in case there is a risk of eye corrosion. It is important to read the whole label carefully and use the product as intended. Keep away from eyes. If product gets into eyes rinse thoroughly with water. Skin corrosion Depending on the concentration at which the ingredient is added to make the final product effective, the final product may have skin corrosive properties. In Europe, the pictogram appears on the label of household detergents and cleaning products in case there is a risk of skin corrosion. For products that are skin corrosive, avoid skin contact at all times. The use of gloves will be recommended. It is key to follow this instruction. |

| Ingredient INCI NAME | AMYL CINNAMALview more |

|---|---|

| Other Chemical Names | 2-Benzylideneheptanal |

| EC number | 204-541-5 |

| CAS number | 122-40-7 |

| Function | Amyl cinnamal is used in Detergent and Maintenance Products as a Fragrance Fragrances provide many sensorial benefits when used in cleaning products and laundry detergents and play a major role in product choice for consumers. Its benefits are both emotional (such as by signifying cleanliness, freshness or comfort) and functional (masking malodour). Fragrance is a key differentiator between products. |

| Regulatory actions to ensure safe use | Safe use assessed by experts along the supply chain https://echa.europa.eu/fr/substance-information/-/substanceinfo/100.004.129 |

| Regulatory measure under consideration - Status | |

| Date of updated information | Aug-20 |

| Risks | The Risk of an ingredient is based on its’ Hazards related to the Exposure Skin sensitization : When exposed, those with an existing allergy may be triggered and have an allergic (skin) reaction to this ingredient. Thus, companies add these ingredients in the smallest effective quantity to ensure the positive effect in the detergent and list the ingredient on the label and online. This is done so that those with allergies can make informed choices and avoid products with ingredients that they are allergic to. |

| Ingredient INCI NAME | Sodium Laureth Sulfateview more |

|---|---|

| Other Chemical Names | Alcohols, C12-14, ethoxylated, sulfates, sodium salts |

| EC number | 221-416-0/ - / 500-234-8 / - / 500-223-8 / 293-918-8 |

| CAS number | 3088-31-1 / 9004-82-4 / 68891-38-3 / 1335-72-4 / 68585-34-2 / 91648-56-5 |

| Function | Sodium Laureth Sulfate is used in Detergent and Maintenance Products as a Nonionic Surfactants Surfactants are key ingredients. They act by changing the surface tension of water to assist cleansing, wetting surfaces, foaming, and emulsifying, to remove particles of dirt and soil. These surfactants do not have an electrical charge, which makes them resistant to water hardness deactivation. They are excellent grease removers that are used in laundry products, household cleaners and hand dishwashing liquids |

| Regulatory actions to ensure safe use | REACH registered Safe use assessed by experts along the supply chain Under review by EU Authorities for additional concerns |

| Regulatory measure under consideration - Status | Data generation, dossier evaluation |

| Date of updated information | Aug-20 |

| Risks | The Risk of an ingredient is based on its’ Hazards related to the Exposure In Europe, the pictogram () appears on the label of household detergents and cleaning products in case there is a risk of eye corrosion. It is important to read the whole label carefully and use the product as intended. Keep away from eyes. If product gets into eyes rinse thoroughly with water. Environmental concerns of surfactants To be placed on the market in Europe detergents have to follow the European Detergent Regulation which requires all types of surfactants used in detergents and maintenance products to be readily and ultimately biodegradable. |

| Ingredient INCI NAME | Benzylhemiformalview more |

|---|---|

| Other Chemical Names | Methanol, (phenylmethoxy) |

| EC number | 238-588-8 |

| CAS number | 14548-60-8 |

| Function | Benzylhemiformal is used in Detergent and Maintenance Products as a Preservative Water-based liquid detergents need a method of preservation, without this they would be contaminated by micro-organisms and result in product going to waste. Preservatives thus play a fundamental role in preventing product damage. They ensure durable shelf and storage life, thereby reducing product losses, and support sustainability by optimising use of resources |

| Regulatory actions to ensure safe use | Reviewed under the Biocidal Products Regulation (EC) 528/2012 as well as REACH For the Biocidal Products Regulation, under assessment of review programme (PT 6 & PT13) https://echa.europa.eu/fr/substance-information/-/substanceinfo/100.035.065 |

| Regulatory measure under consideration - Status | No obvious regulatory activity |

| Date of updated information | Sep-21 |

| Risks | The Risk of an ingredient is based on its’ Hazards related to the Exposure When the product is used according to the label and goes down the drain. These concerns are covered once the product reaches Sewage Treatment Plants, which is required by the Wastewater Treatment Directive. See https://cleanright.eu/en/faq.html (Detergents and our environment) |